api 5l psl2 impact test|api 5l pipe strength : member club API 5L grade X52 (L360 pipe) the yield strength minimum at 52220 Psi 360 Mpa, it’s the meaning that we call this grade in the API 5L X52 or L360. Tensile strength is 66700 Psi and 460 . See more web20 likes, 6 comments - emporioseteitumbiara on February 26, 2024: "Nós sempre acreditamos que a moda não é só para deixar homens mais bonitos, e sim permitir qu." .

{plog:ftitle_list}

8 de jan. de 2023 · FunkyTown Gore Rare Footage (18+) WorthNot. Jan 08, 2023. ( more info) Subscribe 25. 564.net/onion. Wad:1846220. Acc:old_N0H. Embed.

API 5L Pipe Data Sheet, other grades specifications in API 5L. API 5L X52 Pipe Data Sheet, including PSL1, PSL2, and Sour Services. See more

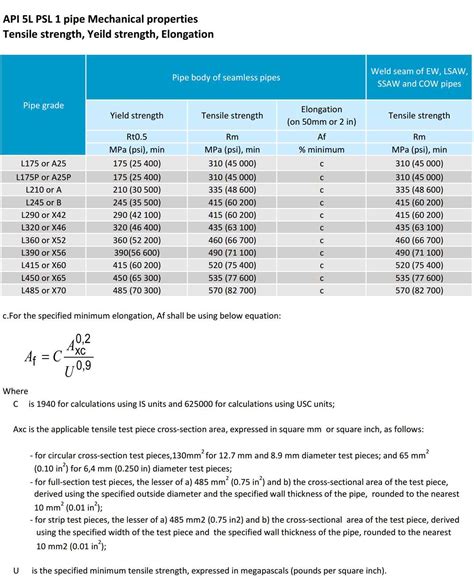

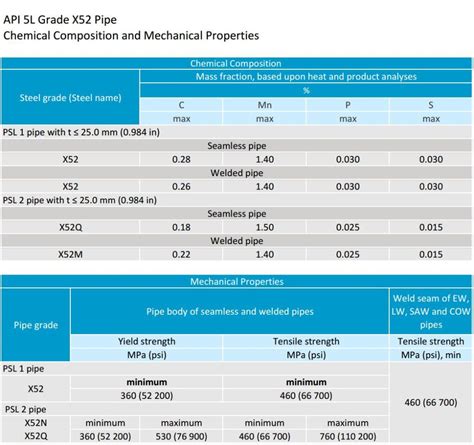

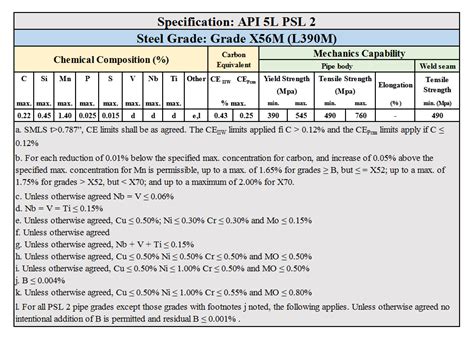

API 5L grade X52 (L360 pipe) the yield strength minimum at 52220 Psi 360 Mpa, it’s the meaning that we call this grade in the API 5L X52 or L360. Tensile strength is 66700 Psi and 460 . See moreAPI SPECS 5L Gr. X52 or L415 Standard: API 5L, ISO 3183 Grade: X52 or L390 (Suffix letter N, Q, M, R) Type seamless steel pipe: 21.3mm – . See moreItem 1 3756 meters carbon steel pipe API 5L X52 PSL2 (ISO 3183 L-360N) OD 20” with type of LONGITUDINAL SUBMERGED ARC WELDING (LSAW), WT 0.562”, should provide with outer (external) coating SYSTEM EQUIVALENT BONDED EPOXY . See more PSL-1 is a loose standard quality for API 5L pipe, whereas PSL-2 contains additional testing requirement, stricter chemical physicals, along with different ceiling limits of .

PSL1 has stricter requirements than PSL2 in terms of chemical composition, tensile properties, impact test, nondestructive testing, and other indicators. For more details, please click here . Testing Requirements for API 5L Pipes Charpy V-Notch (CVN) Impact Test. The CVN impact test is required for many PSL2 pipe sizes and grades. This test measures the .

CVN impact test for PSL2. Many PSL2 pipe sizes and grades require CVN. Seamless pipe is to be tested in the body. Welded pipe is to be tested in the body, pipe weld and heat-affected zone. Refer to the full API 5L . Impact Testing: Charpy impact testing is required for PSL2, especially in low-temperature environments to ensure the pipe’s toughness and ability to resist brittle fractures. .

PSL1 is generally use which equivalent to ASTM A106 B and A53 B. PSL2 is a higher specificaiton level pipe, has more strict value on chemical and mechanical strenth. More over PSL2 requires more test methods like None Distructive .

PSL1 has stricter requirements than PSL2 in terms of chemical composition, tensile properties, impact test, nondestructive testing and other indicators. Impact Test. PSL1 does not require impact test, while it is required for PSL2 .API 5L is suitable for transporting gas, water, and oil, and is usually found in the hydrocarbon petroleum and natural gas industry. The API committee issues standards in regards to these . From these 5 aspects we can distinguish API 5L PSL1 and PSL2. This tells the exact requirements for API 5L standard pipe. API 5L specification is suitable for transporting gas, water, and oil.

Testing Requirements for API 5L Pipes Charpy V-Notch (CVN) Impact Test. The CVN impact test is required for many PSL2 pipe sizes and grades. This test measures the pipe’s ability to absorb energy and resist fracture, ensuring its performance in extreme conditions. The CVN impact test helps to ensure that the pipes can withstand the harsh . API 5L PSL 1 and PSL 2 In API 5L specification, what are the main differences between them? We compare them in these 5 aspects. Toggle navigation. . And it requires Charpy impact testing conditions. From these 5 . Impact Testing: PSL1 does not require impact testing, while PSL2 mandates full-size impact testing at 0°C (32°F) for all grades except X80. For PSL2, the average impact energy (Akv) for full-size samples must be at . This pipeline is PSL 2 according to the API 5L standard and has been withdrawn from service. Charpy tests were conducted according to the ASTM E23 standard using a Charpy machine model 74 with a 0–274 ft-lb capacity. . ASTM E23, Standard Test Methods for Notched Impact Testing of Metallic Materials (2018). ANSI/API 5L Specification for Line .

In proposal, our client request using ASTM A53 Grade B or API 5L Grade B PSL2. We order ASTM A53 Grade B; Client said that: in our certificate, ASTM A53 Grade B did not present the equivalent with API 5L Grade B PSL 2 (such as: did not have impact test, etc.) that why ASTM A53 Grade B may be can consider equivalent with API 5L PSL1.API 5L X60 is a common high grade pipe material in API 5L specifciations for oil and gas transmissions. It’s also called L415 pipe, which named by yield strength minimum in 415 Mpa (60,200 psi).It covers manufacturing types in seamless (hot rolled and colde rolled), and welded in ERW, LSAW, SSAW (HSAW).. API 5L X60 pipe ranges in PSL1, PSL2, onshore/offshore, and .API 5L PSL1 Vs. PSL2 Differences, Comparison and Specification Data Sheet, Supplied by Savoy Piping Inc. PSL-1 is a loose standard quality for line pipe, whereas PSL-2 contains additional testing requirement, stricter chemical physicals, along with different ceiling limits of mechanical properties, and require Charpy impact testing conditions API 5L X42, X46, X52, .%PDF-1.6 %âãÏÓ 10421 0 obj > endobj 10443 0 obj >/Filter/FlateDecode/ID[576E869C78DF3940950884D6C943B26F>]/Index[10421 34]/Info 10420 0 R/Length 110/Prev 2870894 .

API 5L PSL2 Pipe chemical properties: Chemical Composition for API Sour Pipe. a. If C > 0.12%, CEIIW limits shall be applied; If C ≤ 0.12%, CEPCM shall be applied. . Guided-bend test CVN impact test for PSL2 pipe (including pipe body tests, pipe weld and HAZ tests) DWT test for PSL2 welded pipe. Surface Conditions, Imperfections and Defects .API 5L GR B PSL2, API 5L X60 PSL2, API 5L X65 PSL2, API 5L X65, API PIPE EXPORTER, API PIPE SUPPLIER, apispecification.com Phone : +91 22 43431313 Email : [email protected]

In this article, I will explain about PSL1 Vs PSL2 API 5L Linepipe. Many people find it difficult to identify differences between PSL1 And PSL2 Pipes. (PSL1 Vs. PSL2 Pipes) Please subscribe to my channel to get regular updates on the new video. If you like this video, please share this video with your friends and help me to grow my channel.Hydrostatic Test: The pipe under API 5L X70 shall perform the hydrostatic test without leakage 100%. . CVN impact test (Performed for PSL2 pipe including pipe body tests, pipe weld and HAZ tests) DWT test (For PSL2) API 5L X70 PSL2. The raw material of PSL2 steel pipe should be fine grained killed steel. And the coil or steel plate used for .For other sizes refer to the full API 5L specification. CVN impact test for PSL2. Many PSL2 pipe sizes and grades require CVN. Seamless pipe is to be tested in the body. Welded pipe is to be tested in the body, pipe weld and heat-affected zone. . API 5L PSL 1 VS. PSL 2 COMPARISON SPEC SHEET. PSL 1 PSL 2; Grade range: A25 through X70: GR B .API 5L Standard Scope. API 5L is the standard specification for the samless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries. It includes the requirements for the manufacture of two product specification level (PSL1 and PSL2) API 5L is not applicable to cast pipe.

API 5L PSL2 steel pipe, except grade X80, API 5L steel pipe of other grades shall be subject to 0 ℃ impact test. Average value of Akv: longitudinal ≥ 41j, transverse ≥ 27j. All dimensions of API 5L X80 PSL2 pipeline pipes shall be subject to 0 ℃ impact test, and the average value of Akv: longitudinal ≥ 101J, transverse ≥ 68J.

api 5l yield strength

Different impact test methods for PSL1 and PSL2. Bay. Impact test is not required for API 5L PSL1 steel pipe. API 5L PSL2 steel pipe, except grade X80, API 5L steel pipe of other grades shall be .The API 5L Grade B pipe includes PSL1 and PSL2 line pipes, and they are classified according to the different end uses and service requirements. . During the impact test for API 5L line pipe production, steel samples are taken from .

Different impact test methods for PSL1 and PSL2. b. API 5L PSL1 steel line pipe not required to do the impact test. For API 5L PSL2 steel line pipe, except Grade X80, all the other grades of API 5L line pipe required the impact test at temperature of 0℃. The average value of Akv: longitudinal direction≥41J, tranverse direction≥27J.ISO certified API 5L Grade X65 Pipe suppliers in India, API 5l X65 seamless pipe, API 5l X65 Psl1 & Psl2 Pipes in Schedule 40 to SCH 160 at a low price, buy L450 Pipe, check Schedule 40 X65 welded pipe stock. . CVN impact test for PSL2. Many PSL2 pipe sizes and grades require CVN. Seamless pipe is to be tested in the body.Execution: seamless or welded (seamless pipes may be used up to 24 inches, LSAW above 24 inches, ERW up to 20 inches); Specification level (API PSL1, PSL2): PSL1 is a standard quality used for pipelines, whereas PSL2 sets more stringent chemical, mechanical properties, and testing requirements; Surface finish: black, varnish painted, anti-rust oil, galvanized, coated .

API 5L PSL2 pipes are a crucial component in various industries, including oil and gas, water transportation, and construction. These pipes are designed to meet stringent standards and specifications to ensure reliability, durability, and safety. One of the critical requirements for PSL2 pipes is impact toughness, which refers to the ability of the material to absorb energy .

Standard Scope: The scope of API 5L pipe mainly includes the application of the pipe for water and oil and gas pipeline transmission. Manufacturing types: The specification includes the manufacturing types as welded and seamless.Cast pipes are not covered in the specification. Pipes under 24″ are usually seamless or ERW, whereas large diameter pipes are SAW/DSAW. For API 5L pipe X42 to X60 used for both an above and below ground B31.4 pipeline facility being purchased to PSL-2 what should the CVN test temperature be spec . it behoves you to purchase the base materials impact tested at -20 F or below. If this is not the case, or the design condition is low; e.g., < 50% of the SMYS at -20F, there is .PSL2 is stricter than PSL1 in indicators such as chemical composition, tensile properties, impact energy, and non-destructive testing. 2, PSL1 does not require impact performance, PSL2 all steel grades except x80, full-scale 0℃ Akv average value: longitudinal ≥ 41J, transverse ≥ 27J.Different impact test methods for PSL1 and PSL2. API 5L PSL1 steel line pipe not required to do the impact test. For API 5L PSL2 steel line pipe, except Grade X80, all the other grades of API 5L line pipe required the impact test at temperature of 0℃. The average value of Akv: longitudinal direction≥41J, tranverse direction≥27J.

Product Specification : API 5L, PSL-1, PSL-2. Size: 1/2" to 24", * size above 24” NPS can be arranged on request. Schedule: SCH10, SCH 40, SCH 80, SCH 160 To SCH XXS. as per thickness mention in API 5L. . CVN impact test for PSL2. Many PSL2 pipe sizes and grades require CVN. Seamless pipe is to be tested in the body.treatment, additional testing, manufacturing process, surface coatings or end finish. Typical process of manufacturing Type of Pipe PSL 1 PSL 2 Grade A Grade B X42 to X70 B to X80 X80 to X100 SMLS LFW HFW LW SAWL SAWH SMLS – Seamless, without weld LFW – Low frequency welded pipe, <70 kHz

is acls test hard

webestrelabet casino is the innovative casino that has all the things you as a player want such as Free Spins, bonuses and loads of casino games.

api 5l psl2 impact test|api 5l pipe strength